All impact crushers use speed to crush!!

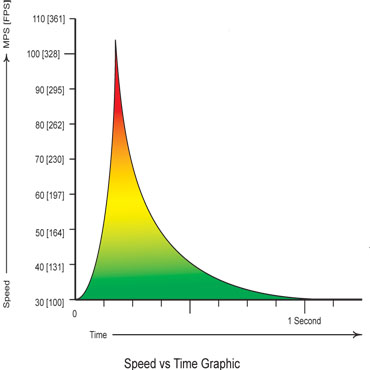

While many factors affect the crushing efficiency of impact crushers, the most important of these are material velocity. The velocity determines the amount of crushing done and the overall grading of the crusher discharge. Generally, the faster the material is accelerated, the greater the amount of crushing achieved.

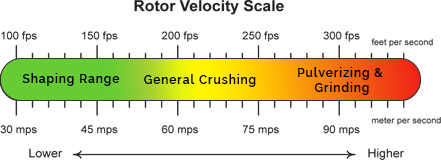

REMco vertical shaft impact crushers have the broadest operating range of all VSI crushers. Please refer to the rotor velocity scale chart. For material reduction, the general velocity range is for particles traveling from 100 feet per second (30 MPS) to 325 feet per second (100 MPS).

How Is Speed Applied to a REMco VSI?

REMco VSI crushers use a rotating impeller that acts as a rock pump to accelerate and impart speed onto the rock particles which are fed to it. Depending on the model and particular application, the rotor configuration and geometry can be varied to suit. A common feature of all REMco rotors is their unique internal construction, using the most efficient port configuration to accelerate the incoming feed stream into multiple flows.

As the rocks are fed to the crusher, each particle experiences a rapid acceleration and deceleration in microseconds. This fills the crushing chamber with a violent rock cloud. Depending on the desired product, the crushing forces applied can be controlled by the operating speed of the machine. This speed control, when combined with a variety of crushing chamber features, results in optimum crushing efficiency for the power employed.

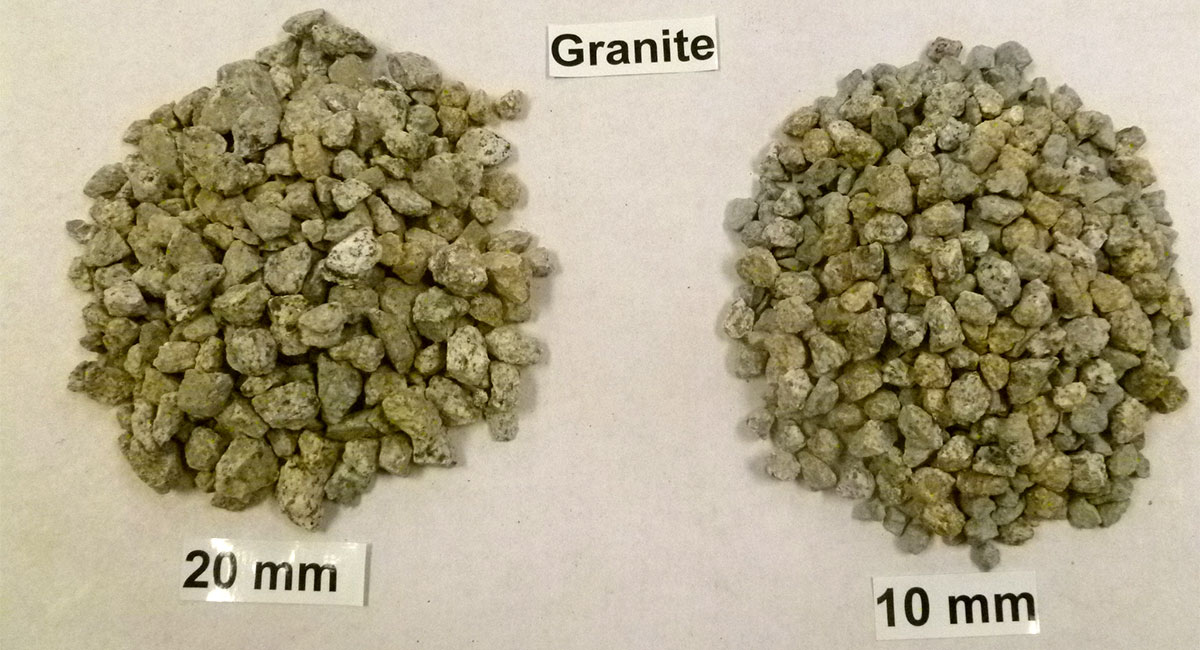

Hard rocks may only be shaped at crushing speeds and soft rocks can often be crushed at shaping speeds.